المنتجات الساخنة

Gyratory Crusher an overview ScienceDirect Topics

网页Gyratory Crusher. A gyratory crusher includes a solid cone set on a revolving shaft and placed within a hollow body, which has conical or vertical sloping sides. From: Handbook

Contact

A comparative study between cone crushers and

网页2011年2月1日 The scope of the present stone is to examine the effect of crusher parameters on crusher performance and to compare the output from a real crusher with

Contact

Gyratory Crusher vs. Cone Crusher: What's the Difference?

网页2023年2月23日 Key Differences between Gyratory Crusher and Cone Crusher. The key differences between gyratory crushers and cone crushers can be broken down into a few

Contact

Principle of a cone or gyratory crusher.

网页Cone crushers are high-efficiency particle crushing instruments utilized in a variety of industries [1]. The crushing chamber is one of the core components of a cone crusher [2], and is directly

Contact

Understanding the Pros and Cons of Gyratory and Cone

网页Comparison of Operating Principles. Cone crushers and gyratory crushers have different operating principles, which affect their performance and efficiency in the crushing

Contact

Cone Crusher Working Principle Animation

网页2012年8月15日 Cone crusher and gyratory crusher work on the same principle. Both have the same operation. If cone crusher differs then it is only from crushing chamber. Cone crusher has a less steep crushing

Contact

How to distinguish between Cone Crusher and Gyratory Crusher?

网页2021年11月24日 The shape comparison of the crushing cavityThe two cones of the gyratory crusher are both steeply inclined, the moving cone is upright, and the fixed cone

Contact

Gyratory CrusherCone Crusher Mantle

网页2015年7月25日 Gyratory CrusherCone Crusher Mantle Differences. Difference between jaw crusher and gyratory crusher. Any of you that are at all familiar with the Gyratory crushers and Cone Crushers that the former

Contact

Gyratory Crusher l Introduce, Working Principle

网页Gyratory Crusher VS Cone Crusher. 1. The two cone shapes of the gyratory crusher are steeply inclined. The movable cone is upright, and the fixed cone is an inverted truncated cone which in order to increase the need

Contact

Gyratory and Cone Crusher ScienceDirect

网页2016年1月1日 The feed size to a gyratory crusher is 2.54 cm and nearly uniform. The product analysis is given in column (2) in the table below. The power required to crush the feed was 500 kW. The clearance between the crusher head and cone was then reduced yielding a product whose size distribution was given in column (3) of the same table.

Contact

Cone Crusher an overview ScienceDirect Topics

网页Cone crushers have gained such wide acceptance that they may be regarded as standard in the intermediate-range size-reducing machines. A schematic diagram of a cone crusher is shown in Fig. 4.6 A.The drive is similar to that of a gyratory crusher. The inner cone or ‘crushing head’ is supported by the tapered concentric spindle, which is rotated by the

Contact

Simulation and optimization of gyratory crusher

网页2020年7月1日 Finally, based on the iron ore coarsely crushed by the gyratory crusher, the dynamic characteristics of the C900 cone crusher were simulated by using the discrete element method (DEM), and the

Contact

Gyratory Crusher vs. Cone Crusher: What's the Difference?

网页2023年2月23日 In terms of design and construction, gyratory crushers and cone crushers have distinct differences. A gyratory crusher has a mantle that rotates within a concave bowl, while a cone crusher has a mantle that rotates within a bowl-shaped concave. This design allows for a larger feed size and a higher capacity for both types of crushers, but

Contact

Crusher an overview ScienceDirect Topics

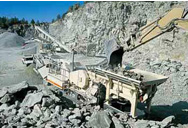

网页13.3.1.1 Primary Crusher. Primary crushers are heavy-duty rugged machines used to crush ROM ore of (−) 1.5 m size. These large-sized ores are reduced at the primary crushing stage for an output product dimension of 10–20 cm. The

Contact

Cone crusher basics in 4 minutes SRP

网页Cone crusher basics in 4 minutes. This is the starting point for understanding how cone crushers work and how they can make your mine or quarry more productive. Elsewhere on the site you can find detailed information about all aspects of crushing and screening, but to make sense of these it helps to understand the basics of cone crushing

Contact

Cone Crusher Working Principle Animation

网页2012年8月15日 Cone crusher and gyratory crusher work on the same principle. Both have the same operation. If cone crusher differs then it is only from crushing chamber. Cone crusher has a less steep crushing

Contact

(PDF) SIZE REDUCTION BY CRUSHING METHODS

网页2017年3月4日 The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling. [4, 5] crusher [4] The tie rod and compression spring ensure that the

Contact

working principle comparison between cone crusher and gyratory crusher

网页Working principle of gyratory crusher,gyratory crusher Working principle of gyratory crusher. crushing cone, center frame body, beams, original dynamic part, oil cylinder, pulley,appliances and dry oil,

Contact

Chamber Optimization for Comprehensive Improvement of Cone Crusher

网页2021年3月15日 This study aims to analyze the impact of key structural parameters such as the bottom angle of the mantle, the length of the parallel zone, and the eccentric angle on the productivity and product quality of the cone crusher and optimize the crushing chamber to improve the crusher performance. The amount of ore in the blockage layer was

Contact

Gyratory and Cone Crusher ScienceDirect

网页2016年1月1日 The feed size to a gyratory crusher is 2.54 cm and nearly uniform. The product analysis is given in column (2) in the table below. The power required to crush the feed was 500 kW. The clearance between the crusher head and cone was then reduced yielding a product whose size distribution was given in column (3) of the same table.

Contact

Simulation and optimization of gyratory crusher

网页2020年10月1日 To study and optimize the gyratory crusher performance, taking the process of crushing iron ore by the gyratory crusher as the specific analysis object in this . First, the discrete element method (DEM) analysis model of the iron ore based on the bonded-particle model (BPM) is established. On this basis, the impacts of the mantle

Contact

Simulation and optimization of gyratory crusher

网页2020年7月1日 Finally, based on the iron ore coarsely crushed by the gyratory crusher, the dynamic characteristics of the C900 cone crusher were simulated by using the discrete element method (DEM), and the

Contact

Chamber Optimization for Comprehensive Improvement of Cone Crusher

网页2021年3月15日 This study aims to analyze the impact of key structural parameters such as the bottom angle of the mantle, the length of the parallel zone, and the eccentric angle on the productivity and product quality of the cone crusher and optimize the crushing chamber to improve the crusher performance. The amount of ore in the blockage layer was

Contact

Cone crusher basics in 4 minutes SRP

网页Cone crusher basics in 4 minutes. This is the starting point for understanding how cone crushers work and how they can make your mine or quarry more productive. Elsewhere on the site you can find detailed information about all aspects of crushing and screening, but to make sense of these it helps to understand the basics of cone crushing

Contact

sbm/sbm compare and contrast a gyratory crusher and cone crusher

网页Contribute to sili2023/sbm development by creating an account on GitHub.

Contact

The detailed explanation of advantages and disadvantages of the cone

网页2021年4月1日 5. It has a spring safety system and overload protection capability, which can effectively discharge the choking iron and improve the ability of the cone crusher to cope with emergencies; 6. The

Contact

working principle comparison between cone crusher and gyratory crusher

网页Working principle of gyratory crusher,gyratory crusher Working principle of gyratory crusher. crushing cone, center frame body, beams, original dynamic part, oil cylinder, pulley,appliances and dry oil,

Contact

Difference Between Jaw Crusher and Gyratory

网页Some of the crushing ratios can reach 13.5, and the work is smooth, vibration is small. Jaw crusher is intermittent crushing, crushing efficiency is relatively low. The feeding way is different, any side of the gyratory

Contact

What The Difference Between Cone Crusher And Gyratory Crusher

网页24-CRUSHER-Stages of the Crushing #2fishygirl on Scribd . The choice between Gyratory crushers and jaw crushers is . A major difference between the two is Gyratory Cone crusher the shape of the head crushing head and .

Contact